0 Comment(s)

0 Comment(s) Print

Print E-mail China.org.cn, March 8, 2024

E-mail China.org.cn, March 8, 2024

Goldeer, renowned for its mosquito-repellent incense, has long been a household name in China. Operating from Quanzhou, a significant manufacturing hub in southeastern China, the company has traditionally relied on combining low prices with high quality to compete in the domestic market. However, this strategy is now being tested in the fiercely competitive daily chemicals market.

A worker works at a production line in Goldeer in Quanzhou, southeastern China's Fujian province. [Photo provided to China.org.cn]

Like many companies in traditional manufacturing industries, whose added value constitute nearly 80% of China's total manufacturing sector, Goldeer is actively accelerating its efforts to upgrade and transform.

The company has prioritized research and development to encourage continuous innovation, according to Zhang Hongzheng, the company's general manager. It established a provincial-level R&D center in 2008 and formed a dedicated team to develop cutting-edge technological products. So far, it has yielded more than 70 patented new technologies.

To boost the competitiveness of its flagship products, Goldeer upgraded the drying processes of its mosquito-repellent incense, thus increasing production efficiency by 15%. In 2022, the firm launched new projects for insecticide aerosols and baits targeting red fire ants and flies. One of the products, a cockroach killer gel bait, became highly popular on e-commerce platforms, selling 300,000 units a month on the short-video platform Douyin alone.

Goldeer is just one example of a traditional manufacturing enterprise striving for innovation to remain competitive.

According to a government report, in 2022, Chinese enterprises above the designated size in the textile manufacturing industry, including textile, apparel, and chemical fiber manufacturing, spent a total of 53.5 billion yuan ($7.4 billion) on R&D. This marked an increase of 1.97 billion yuan compared to the previous year, representing a growth rate of 3.82%.

China's total R&D spending in 2023 grew 8.1% year on year to over 3.3 trillion yuan, with R&D intensity rising to 2.64%, according to the Ministry of Science and Technology.

Zhang from Goldeer mentioned that their new products, which feature novel functionalities and distinctive packaging, have gained popularity across numerous countries in South America, Africa, the Middle East, and Southeast Asia.

"The company will further boost its R&D capabilities, striving to explore higher-value-added fields to expand its industrial chain," he said.

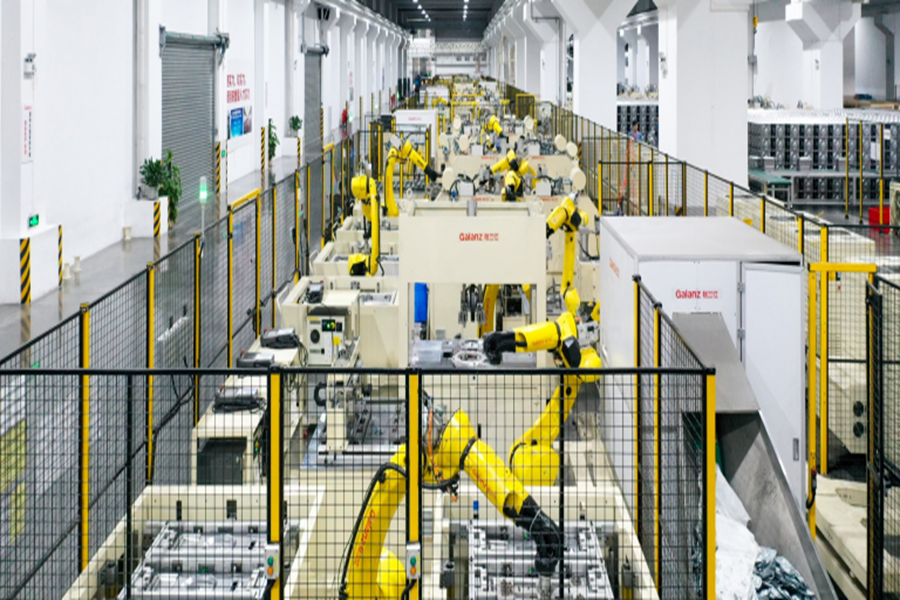

Galanz, a home appliance manufacturer, is another vivid example of traditional Chinese manufacturers pursuing sustainable growth.

Since 2012, Galanz has accelerated its transformation toward smart manufacturing, progressively increasing investment in automation and intelligent manufacturing across its entire industry chain.

Galanz Industry 4.0 Base in Shunde, southern China's Guangdong province. [File photo]

In 2019, the company unveiled the world's first proprietary Internet of Things home appliance chip, the "BF-Xijiang," marking a pivotal step in its digital technology transformation and further ensuring the stability of its industrial chain.

Liang Zhaoxian, president of Galanz, stated that the company has achieved a high level of autonomy and control over the entire industry chain, from microwaves to comprehensive home appliances, to secure its sustainable future development.

In 2022, Galanz reported a 5.1% year-on-year increase in total sales across all categories in the Chinese market. Notably, microwave oven sales rose nearly 10% year on year, while sales of built-in steam ovens surged 75% compared to the previous year.

The Chinese government has long been focused on upgrading and transforming traditional industries.

According to a guideline jointly released late last year by eight departments, including the Ministry of Industry and Information Technology (MIIT), China aims for its traditional manufacturing sector to achieve notable advancements in high-end, intelligent, green, and integrated development by 2027. This initiative is designed to consolidate the sector's position and competitiveness in the global industrial division of labor and cooperation.

The guideline outlines several areas crucial for this transformation, including innovation, digital technology empowerment, green and low-carbon development, industrial integration, and policy support.

Jin Zhuanglong, minister of the MIIT, stated in a recent article that China will place a greater emphasis on transforming its traditional industries. It will do this by employing a comprehensive strategy that includes providing financial support, promoting technological upgrades, nurturing brands, and facilitating industrial transfers both within and outside the country.

Fu Wei, an associate researcher at the Chinese Academy of Social Sciences, suggested that local governments offer more support for developing and transforming traditional industries. He also encouraged traditional manufacturers to embrace digital technologies to accelerate their transformation.